The buzz-words “continuous improvement” have been around for quite a while now. It simply means that the goal is to become better all the time. In our businesses, and even in our homes, we should try to refine our processes to make our lives easier. Sometimes this is a significant change like implementing new customer database software. Often the changes are small but equally time-saving such as using a letter sorter to make files on your desk more visible.

The continuous improvement process, also known as kaizen in industry, was introduced to North American in the mid-1980s. Many people today associate kaizen with The Toyota Way of manufacturing. However, kaizen principles can be applied to all aspects of business, from customer relationships to office administration.

The Continuous Improvement Process

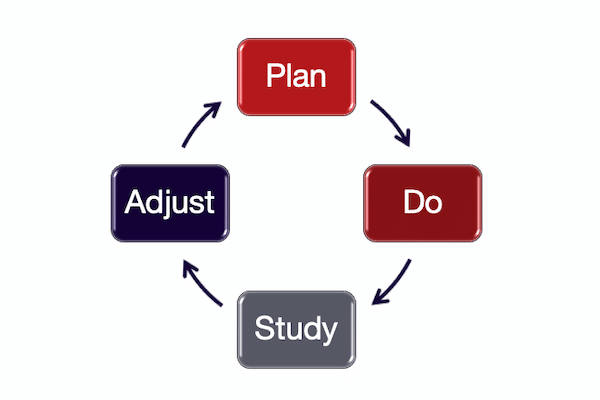

As shown in the illustration above, the cycle of kaizen is based on the Shewhart Cycle: Plan → Do → Study → Adjust

Plan. Determine what is not working well and decide on the best way to make improvements.

- No one can find files on the office’s common hard drive. Work with staff to build a folder structure and create file naming system.

Do. Make improvements.

- Schedule an afternoon for all staff to rename their folders and files. From that point forward all staff use the new naming system.

Study. Evaluate the changes made to see if they really do improve the process.

- Over the next two weeks collect staff feedback on new system.

Adjust. Make modifications or revert to the original system if the changes do not improve the process.

- Rename some ambiguous folders. Reorganize the files in those folders to find them more easily.

The Benefits

Changes are likely to be small and incremental. Smaller changes over time are less expensive to implement than large overhauls all at once. Because changes are proposed by the staff instead of an outside consultant, the changes are more likely to be effective and accepted by the staff. In addition, it can help reinforce teamwork and improve staff motivation and sense of value to the company.

The Dangers

With all the benefits listed above, you might be asking if continuous improvement even has a downside. Yes, it does. I previously discussed the five Ds of decision-making so use that as a guide. In other words, don’t apply continuous improvement principles to tasks you shouldn’t be doing in the first place.

If you need help getting your team into the continuous improvement mindset, Out of Chaos would be happy to help. Check out our Office Productivity and Time Management Services, book Linda for a Productivity Workshop, or contact us for more information through our website.